3M™ Cubitron™ II Fibre Disc 982C

- | Select product options for IDs.

Details

Highlights

- 3M Precision Shaped Grain technology cuts exceptionally fast with less pressure, outperforming all conventional ceramic industrial abrasive discs

- Lasts up to twice as long as conventional discs

- Get significantly longer disc life, completing more parts per disc with fewer disc changes required

- With triangular shaped ceramic grain that wears evenly, runs cool and optimises mineral breakdown

- Durable and tear resistant with a stiff fibre backing and strong resin bond for high pressure weld grinding and bevelling

- Minimise operator fatigue with 3M Precision Shaped Grain reducing grinding pressure

3M™ Cubitron™ II Fibre Disc 982C outperforms conventional ceramic industrial abrasive discs. Our discs feature 3M Precision Shaped Grain technology, offering up to twice the cut rate, durability and lifespan of conventional discs with less grinding pressure required.

Use our heavy duty 3M™ Cubitron™ II Fibre Disc 982C for a variety of applications including edge chamfering, bevelling and removing carbon steel welds, mill scale, pits and imperfections, machining grooves and more. Our discs raise the bar for high performing abrasives, offering up to double the cut rate and lifespan than conventional ceramic industrial abrasive discs, with less grinding pressure required. Use for grinding and blending large and small areas of metal surfaces. In heavy duty applications, more parts per disc are completed, reducing the need for disc changes. Our discs feature 3M Precision Shaped Grain technology, which generates triangular shaped grains, electrostatically positioned on the backing. These turn into sharp peaks that act like individual cutting tools, slicing through metal with extreme efficiency. The grains wear evenly and continuously self-sharpen as the points break off. This reduces heat due to friction and extends the lifespan of the disc. The tough, stiff backing is made from a vulcanized fibre that resists wear and can handle tough grinding applications. Our discs are designed to maximise cutting potential, minimising grinding pressure and operator fatigue.

Typical Properties

Details

| Abrasive Material | Precision Shaped Ceramic |

| Application | Grinding |

| Attachment Type | Center Hole, Slotted |

| Backing Material | Fibre |

| Bond Type | Resin |

| Brands | Cubitron™ |

| Center Hole Diameter (Metric) | 16 Millimetre, 22 Millimetre, 22.225 Millimetre |

| Coat Type | Open Coat |

| Grit | 36+, 60+, 80+ |

| Hole Configuration | 394EO, 453EQ, 492EQ, 500P, 591EQ, 700BB, 709EQ, 906EQ, 912J |

| Industries | Machinery Manufacturing, Transportation, Metal Fabrication |

| Maximum Speed | 6600 rpm, 8500 rpm, 8600 rpm, 10000 rpm, 10200 rpm, 12000 rpm, 13300 rpm, 15000 rpm, 15200 rpm |

| Sanding Type | Wet/Dry |

| Sub Industries | Structural Steel, Farms & Construction, Specialty Vehicle, Rail, Oil & Gas, Ship & Boat Building, Sheet Metal, Industrial |

Dimensions and Classifications

| Overall Diameter (Metric) | 100 Millimeter, 114.3 Millimeter, 115 Millimeter, 125 Millimeter, 127 Millimeter, 150 Millimeter, 177.8 Millimeter, 180 Millimeter, 230 Millimeter, 231.775 Millimeter |

Resources

Data Sheets

(PDF, 144KB)

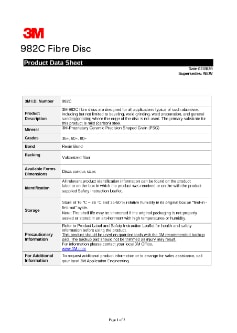

3M™ Cubitron™ II Fibre Disc 982C Technical Data Sheet 0220

3M™ Cubitron™ II Fibre Disc 982C Technical Data Sheet 0220